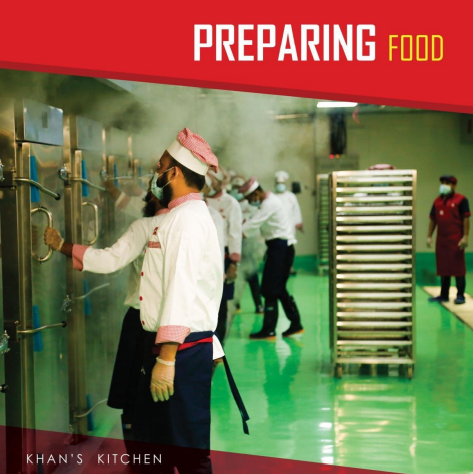

Food Processing

Food Quality Control

- We maintain international standard quality control from gathering raw materials, process food and deliver them.

- We have a dedicated food inspector to check raw materials and finished cooked food.

- We also have another food inspector only assure hygiene food and we strictly monitor sanitization and protection in ICU kitchen area.

- We also have international standard cleaning equipment’s to clean and bacteria free in ICU kitchen.

- After cooking, the cook foods go through our lab test to guarantee hygiene and quality and only qualified foods will be sent for packaging.

- After cooking, the cook foods go through our lab test to guarantee hygiene and quality and only qualified foods will be sent for packaging.

- We maintain international standard of temperature to keep food hygiene.

- We have a separate packaging and containing area.

- After packaging our delivery team will have the responsibility to deliver our foods to your premises.

- We have different zones for preparing vegetable, fish and meat

- Each zone is authorized to certain employees.

- Our main kitchen is called the “Red Zone” which is supervised by designated chefs

- people designated for preprocess of raw materials aren’t allowed in “Red zone” due to hygiene factors.

- We cook our curry, vegetable, soup, dessert and snacks in this “Red zone”.

Protection of Food

- We Use disposable gloves or utensils to serve ready-to-eat food. We do not touch food with bare hands. We also use tongs or spoons for salads and other ready-to-eat items. Each zone is authorized to certain employees.

- We provide single-use eating/drinking utensils and keep them adequately protected from contamination. Provide sauce, mustard and other condiments in squeeze-type dispensers or individual sealed packets.

Raw Materials

- We Source raw materials from licensed and reputable companies.

- We Purchase Raw Materials as close to our Factory as possible to avoid need for storage and reduce transportation times.

- We Source foods on the way to the Factory where possible.

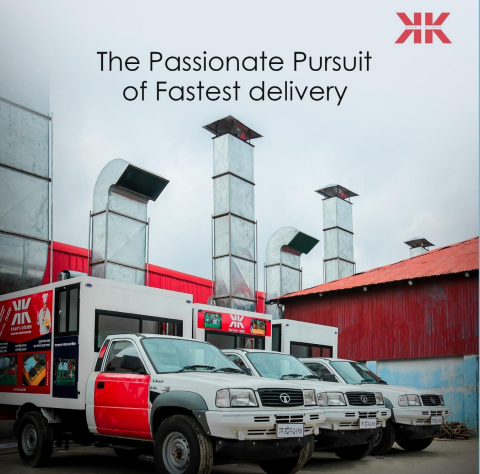

Food Delivery

- We delivery food through our own Customized Delivery Van. We use Separate Van for Raw Food and Cooked Food.

- Potentially hazardous foods are transported under temperature control.

- All containers, portable coolers and parts of vehicles used to transport food are washed and sanitized before and after use.

- Transport raw meats in separate containers from ready-to-eat products such as salads and bread.

Food Storage

- We do not store any food directly on the ground.

- All food is stored inside the stall must be at least 150 mm above the ground and be wrapped, packaged or kept in enclosed containers.

- We stored all food in covered or in sealed containers.

- Raw and ready-to-eat foods are separated to prevent cross-contamination.

Temperature Control

- All cold foods (including raw and cooked meats, prepared salads and dairy products) are stored at or below 5˚C.

- All hot foods are stored at or above 60˚C.

- All frozen food is kept in frozen solid.

- We test the food temperature through food grade thermometer.

- Pre-prepared food products or pre-cooked foods which promote bacterial growth are stored and displayed at a temperature at or below 5˚C.

- Ready-to-eat potentially hazardous food are keep between 5˚C and 60˚C for a short amount of time using the two hours/four-hour rules:

- For a total of less than two hours – refrigerate or use immediately.

- For a total of between two and four hours – use immediately.

- For a total of four hours – must be thrown out.

Cooking, Re-Heating and Cooling Food

- In cooking zone, we carried out adequate provisions to protect the walls, floors and ceiling from heat, flame and splashing.

- All Hot food are re-heated to an internal temperature of 60˚C before serving.

- When cooling cooked potentially hazardous foods, cool the food:

- within two hours – from 60˚C to 21˚C

- within a further four hours – from 21˚C to 5˚C

Health and Hygiene of Food Handlers

- Hands must be washed regularly, including after: Using the toilet, Blowing your nose, Taking breaks, Handling different types of food products,Any other activity that has the likelihood to contaminate hands, food or food contact surfaces.

- All the food handlers have Uniform for hygiene and clean clothing.

- Disposable gloves are changed frequently and hands washed with liquid soap and water.

- When unpackaged food is handled aprons should preferably be worn and long hair should be tied back or held in a hair net.

Cleaning and Sanitizing of Surfaces

- All equipment and food contact surfaces in the kitchen always clean and sanitized both before and after use. Walls, floor and ceiling covering are cleaned daily, or more frequently if they pose a risk of contamination to food or food contact surfaces.

- The correct cleaning steps for food contact surfaces are as follows:

- Wipe away any food scraps and rinse with water.

- Wash with hot water and detergent to remove any grease. Rinse off any loose dirt or detergentfoam with clean water. Sanitize using a food grade sanitizer.

- If instructions require rinsing of the sanitizer, do so.